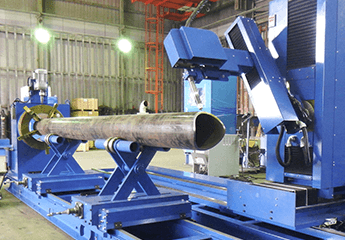

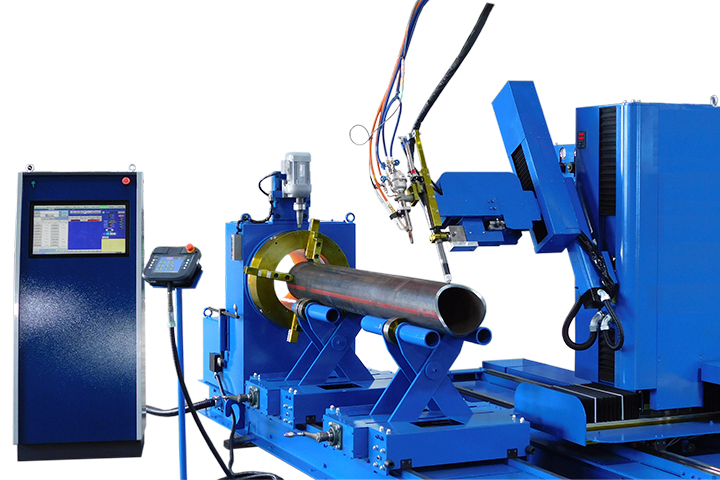

| 仕様/型式 | 400MA | 650MA | 1000MA | 1350MA | 1500MA |

|---|

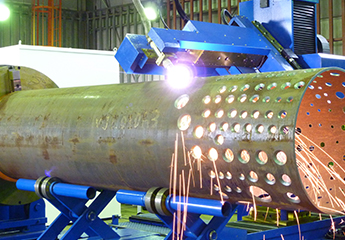

| 切断対象径(mm) | 34〜

406.4 | 60.5〜

660.4 | 76.3〜

1016 | 165.2〜

1371.6 | 267.4〜

1524 |

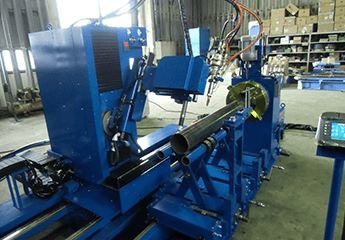

| 対話型切断ソフトウェア

PIPE STUDIO | 5軸(MA5)/6軸(MA6)/7軸(MA7) |

| 対話型操作盤/遠隔操作盤 | 標準搭載 |

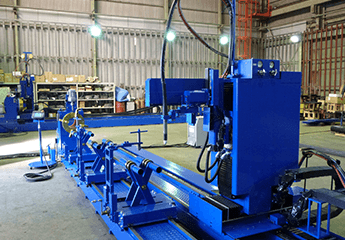

| トーチレール長さ(mm) | 1000/3000/6000/9000/12000/15000/18000 |

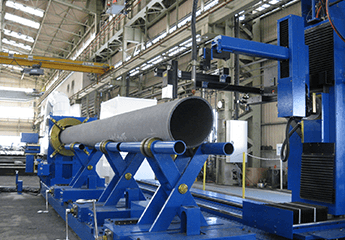

| パイプ受台数 | トーチレール~6000mm x3台/~12000mm以上 x5台 |

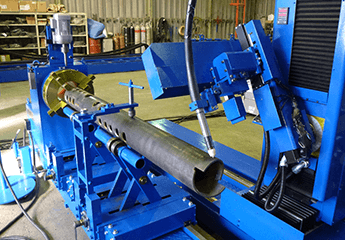

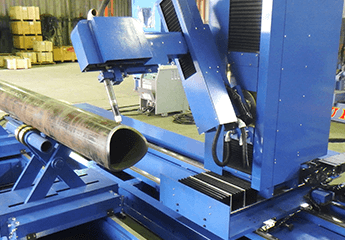

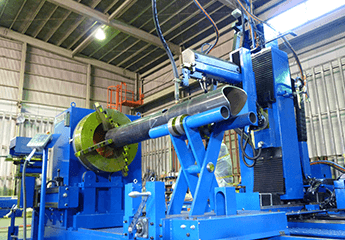

| スクロールパイプチャック | 3爪/4爪/5爪(標準4爪) |

| レーザーセンサーシステム | 標準搭載 |

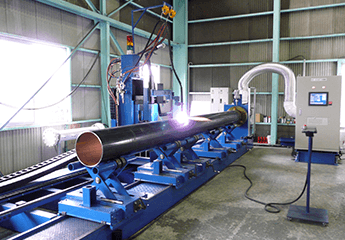

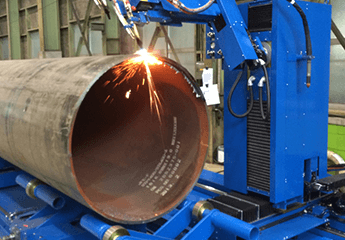

| プラズマ切断装置 | 標準搭載 |

| ガス切断システム | オプション搭載 |

| 手動予熱システム | オプション搭載 |

| 自動マーキングシステム

(パウダーマーキング) | オプション搭載 |

| 自動マーキングシステム

(インクジェットマーキング) | オプション搭載 |

| チャック本締め装置 | オプション搭載 |

| 受台(電動走行) | オプション搭載 |

| 接触式横面倣い | オプション搭載 |

| チャック後方切断 | オプション搭載 |

| 自動搬出入システム

(チャック上下駆動付き) | オプション搭載 |

| 角パイプ回転冶具 | オプション搭載 |

| 集塵装置 | オプション搭載 |

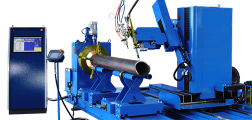

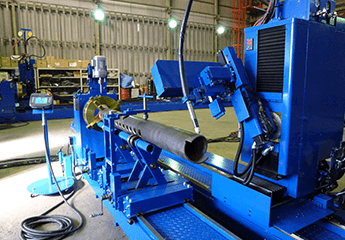

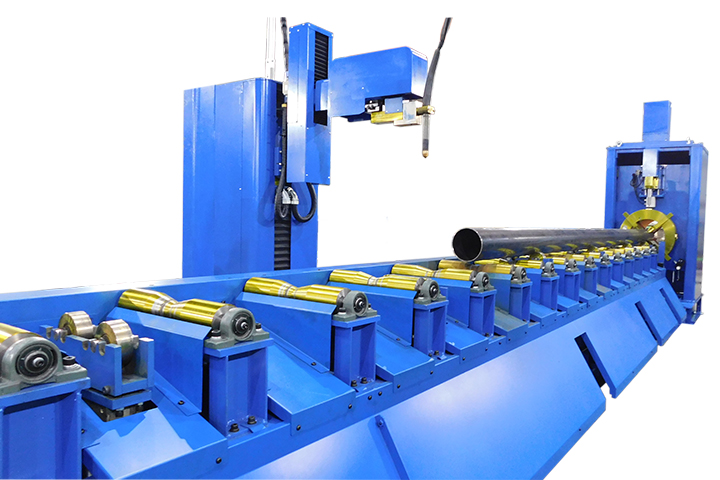

PIPE COASTER

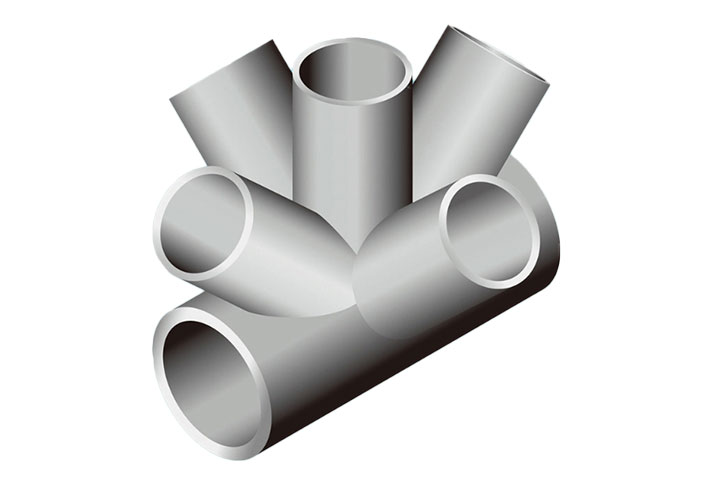

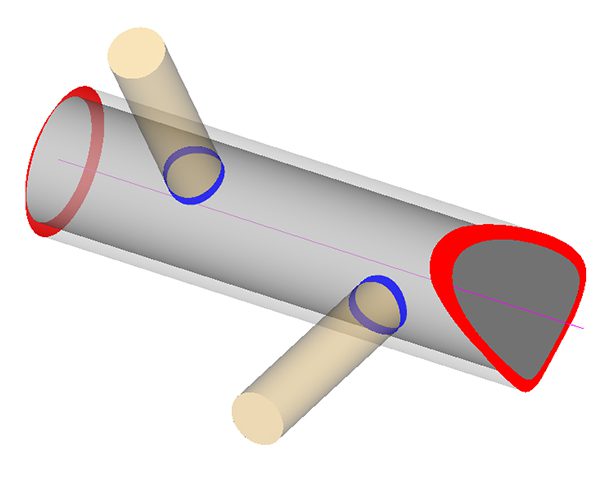

PIPE COASTER  Cutting Shapes

Cutting Shapes  Standard HID Series

Standard HID Series  Special HID Series

Special HID Series  ALL PROFILE COASTER

ALL PROFILE COASTER  Software

Software  Customer Case Study

Customer Case Study  After-sales Service

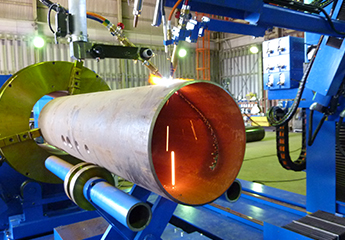

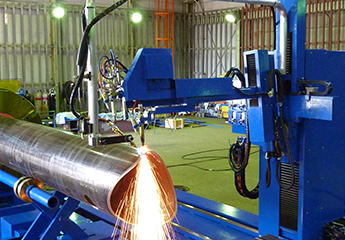

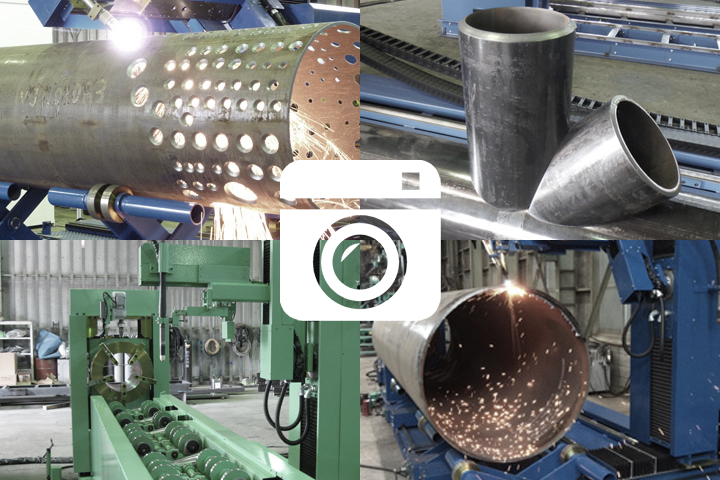

After-sales Service  Photo Gallery

Photo Gallery  Movie Gallery

Movie Gallery  Special Cutting Shapes

Special Cutting Shapes